While the least expensive of all the injection molding processing components, a properly designed and built check valve is extremely important to good processing.

Based on decades of experience, Concor developed the innovative and popular Veloci-T™ Screw Tip.

CONCOR VELOCI-T™ TIP ASSEMBLY

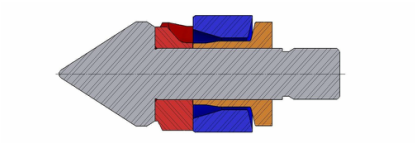

The optimal tip design is the result of decades of experience. This three-piece free-flow injection molding screw tip design has deep smooth flute areas on the allowing a “free flow” of material off the screw. Concor’s Veloci-T™ free flow design has improved shut-off over other free flow valves. Most of Concor's customers prefer the Veloci-T™ free flow 3 piece. Concor stocks a wide range of tips for quick delivery. Click here for a list of manufacturers whose machines we can provide components for.

Veloci-T™ tips provide large front face ring target area and specially engineered rear seat to assure positive shut off of low viscosity (i.e. Nylon) and high filled resins – minimize scrap. Veloci-T™ tips are made of CPM M4 HIPPED tool steel providing high resistance to heat, impact & rotational wear of contact surfaces - extended wear life / reduced cost. Our standard Veloci-T valve is calculated to give you optimum ring travel for the widest variety of materials, but on that special occasion where your shot consistency is floating around because the ring is not seating off quickly enough, Concor does offer a longer check ring to allow quicker shut-off. Some refer to this as a "short throw" check ring.

- Less restrictive than 4 piece or ball check designs

- Reduced wear and material degradation

- Ideal for shear sensitive materials such as PC, ABS, PVC, because the ring floats "free"

- The ring does not rotate with the screw, extending barrel life

- Design allows for processing a variety of materials – provides flexibility for custom molding Design eliminates dead spots minimizing material degradation

- Ring is designed as sacrificial wear component –simple and cost effective.

The optimal tip design is the result of decades of experience. This three-piece free-flow injection molding screw tip design has deep smooth flute areas on the allowing a “free flow” of material off the screw. Concor’s Veloci-T™ free flow design has improved shut-off over other free flow valves. Most of Concor's customers prefer the Veloci-T™ free flow 3 piece. Concor stocks a wide range of tips for quick delivery. Click here for a list of manufacturers whose machines we can provide components for.

Veloci-T™ tips provide large front face ring target area and specially engineered rear seat to assure positive shut off of low viscosity (i.e. Nylon) and high filled resins – minimize scrap. Veloci-T™ tips are made of CPM M4 HIPPED tool steel providing high resistance to heat, impact & rotational wear of contact surfaces - extended wear life / reduced cost. Our standard Veloci-T valve is calculated to give you optimum ring travel for the widest variety of materials, but on that special occasion where your shot consistency is floating around because the ring is not seating off quickly enough, Concor does offer a longer check ring to allow quicker shut-off. Some refer to this as a "short throw" check ring.

- Less restrictive than 4 piece or ball check designs

- Reduced wear and material degradation

- Ideal for shear sensitive materials such as PC, ABS, PVC, because the ring floats "free"

- The ring does not rotate with the screw, extending barrel life

- Design allows for processing a variety of materials – provides flexibility for custom molding Design eliminates dead spots minimizing material degradation

- Ring is designed as sacrificial wear component –simple and cost effective.

LOCKING (CASTELLATED) TIP ASSEMBLIES:

The tip and ring have interlocking cutouts that look similar to a castle turret; hence the name. The ring is always interlocked with the tip and rotates with the screw. It is commonly found on many OEM machines produced in Asia.

The tip and ring have interlocking cutouts that look similar to a castle turret; hence the name. The ring is always interlocked with the tip and rotates with the screw. It is commonly found on many OEM machines produced in Asia.

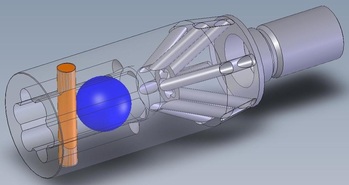

BALL CHECK VALVES:

This design makes use of an internal ball to provide shut off. Designs can be front discharge or side discharge.

- Accurate and consistent shut off

- Good for PP, PE, PS, nylons. Often used with larger presses (over 1000 T)

This design makes use of an internal ball to provide shut off. Designs can be front discharge or side discharge.

- Accurate and consistent shut off

- Good for PP, PE, PS, nylons. Often used with larger presses (over 1000 T)

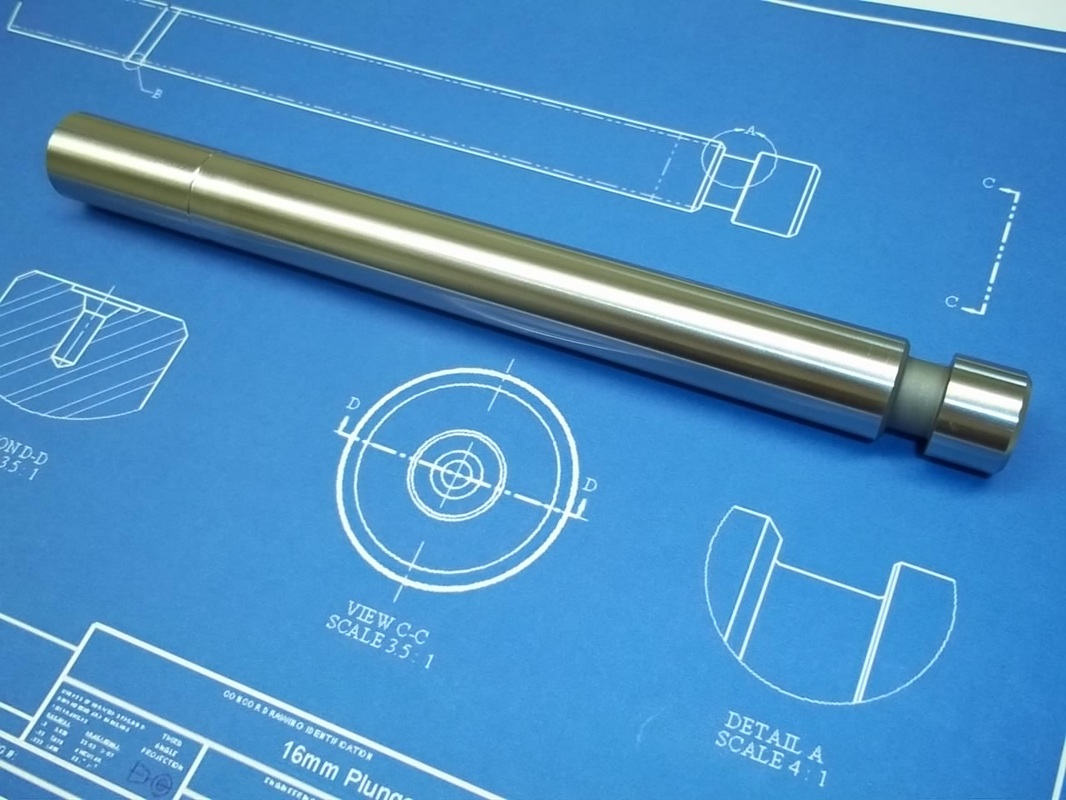

SODICK STYLE PLUNGER FOR SILICONE MOLDING: