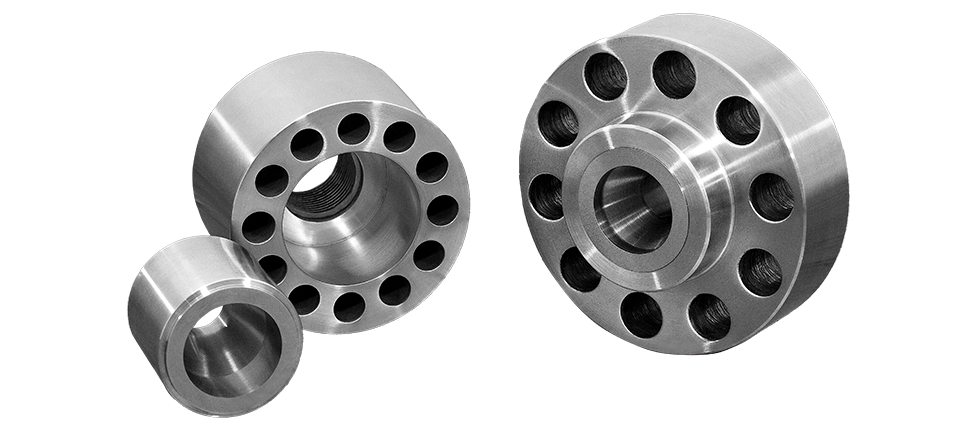

End Caps for Injection Molding and Extrusion Barrels:

Concor manufactures end caps for injection molding and extrusion machines from high strength alloy steel, chrome plated or ion nitrided ID for GP environments with high polished ID surfaces to 8-16 RMS or better.

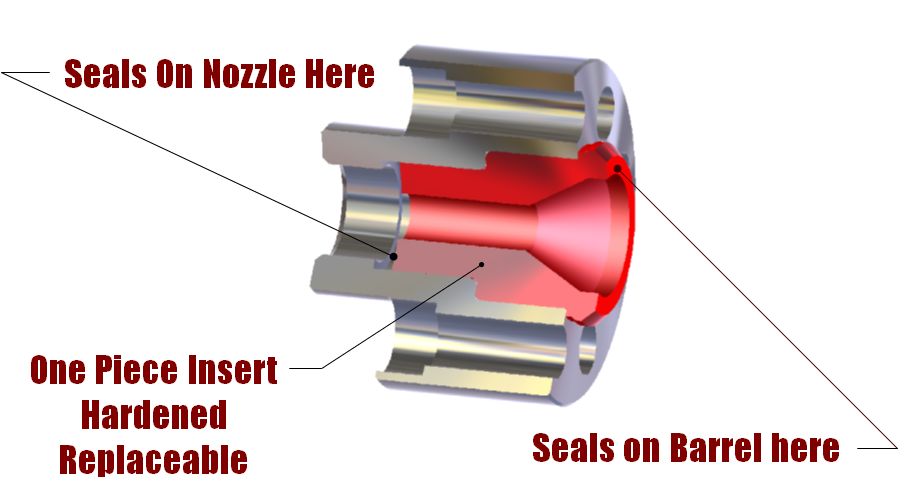

Smart processing: Go for an end cap with a replaceable insert from Concor.

The insert can easily be replaced at a fraction of the cost of a new end cap.

Our inserted design provides optimum benefit. Concor’s insert design end cap provides the strength required to meet the internal pressures, while at the same time, provides the best wear/corrosion protection to the ID with the hardened insert. The insert can be made from a wide variety of materials depending on customer requirements. Most commonly used are D2, CPM 10V and 20CV tool steels. Stainless steels and Hastelloy are often used when facing a corrosive environment.

The importance of a smooth, highly polished finish cannot be overstated. Material can easily collect on a rough finish and degrade. Once those particles break loose, they continue downstream into the mold where the end result is poor product quality and increased scrap rate. The other factor contributes to this issue is the clearance between the tip and the injection molding machine end cap ID. We recommend the clearance from the taper on the tip to the taper on the end cap to be approximately the same as the flight depth in the metering zone of their screw. Keeping these things in mind will go a long way in preventing degradation problems.