You've found the page to learn about screw, barrel, and tip repair and rebuilding. Reduce, reuse, recycle!

Rebuilding and repairing injection molding screws , repairing extrusion feedscrews, and relining barrels are more than just cost saving services. They often provide better wear resistance than when the components were new. Save money and bring your screw or barrel back to like new, or better condition, with Concor's remanufacturing services.

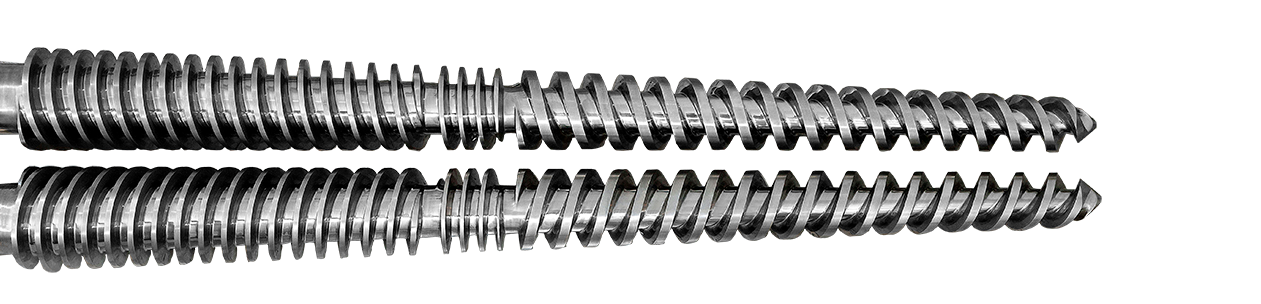

Rebuilding and Repairing Feedscrews

The photo below illustrates the stages of rebuilding a feed screw. The screw is inspected, cleaned up, welded up oversize, any additional repairs made, machined, ground, and polished. They are like new when done. Read below to learn more about how your worn or damaged screw can be rebuilt and modified.

- Screw flights are repaired and rebuilt to SPI standards.

- A variety of hard surfacing materials are available, consult with us on options to suit your application.

- Broken drive end can be replaced and new hot ends can be installed should the tip threads be damaged.

- The screw’s compression ratio can be modified for specific processing applications.

- Mixing sections can be added, modified, and rebuilt.

- Concor pioneered the process of rebuilding CPM 9V through-hardened tool steel screws in the '90's and we are experts in the process. We rebuild CPM 9V through hardened screws.

NEW in 2018!: In 2018 Concor added the capability of rebuilding twin screws to our offering.

Barrel Rebuilding and Relining

- Barrel relining eliminates the need for a new replacement barrel.

- Most barrels can be relined full length or partially relined.

- Several liner grades are available.

- Barrels can be modified to accept a bolt on end cap should the thread on design become a problem.

- Finished rebuilt barrels are fully inspected, including for straightness.

Perfectly straight. Tool steel lined barrel:

Our barrel rebuilding services include rebuilding Krauss Maffei barrels, including the cast portion of the assembly.

Rebuilding Tips, Endcaps, and other parts:

TIP REBUILDING: A tip assembly can have its sealing surfaces reground if the valve is through hardened and the check ring OD is still to size. In addition, the valve is cleaned and polished. There is a minimal cost associated with valve resurfacing.

END CAP REBUILDING: End caps can be "rebuilt" by inserting a through-hardened tool steel insert that provides a wear resistant surface on the ID angle and through hole.

ADDITIONAL REBUILD SERVICES:

1. Extruder gearbox rebuilds

2. Extruder feed throat relining

3. Tie bar repair – new ends and re-chroming

4. Piston and cylinder repair

5. Drive quill repair

6. Drive bushings and retainers

7. Auger repair

8. Plunger repair

9. Carbide coating and surface treatments

10. Hard surfacing

11. Stuffer repair

END CAP REBUILDING: End caps can be "rebuilt" by inserting a through-hardened tool steel insert that provides a wear resistant surface on the ID angle and through hole.

ADDITIONAL REBUILD SERVICES:

1. Extruder gearbox rebuilds

2. Extruder feed throat relining

3. Tie bar repair – new ends and re-chroming

4. Piston and cylinder repair

5. Drive quill repair

6. Drive bushings and retainers

7. Auger repair

8. Plunger repair

9. Carbide coating and surface treatments

10. Hard surfacing

11. Stuffer repair