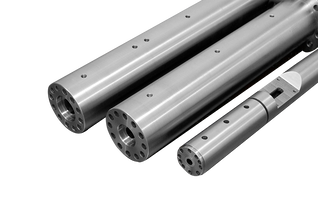

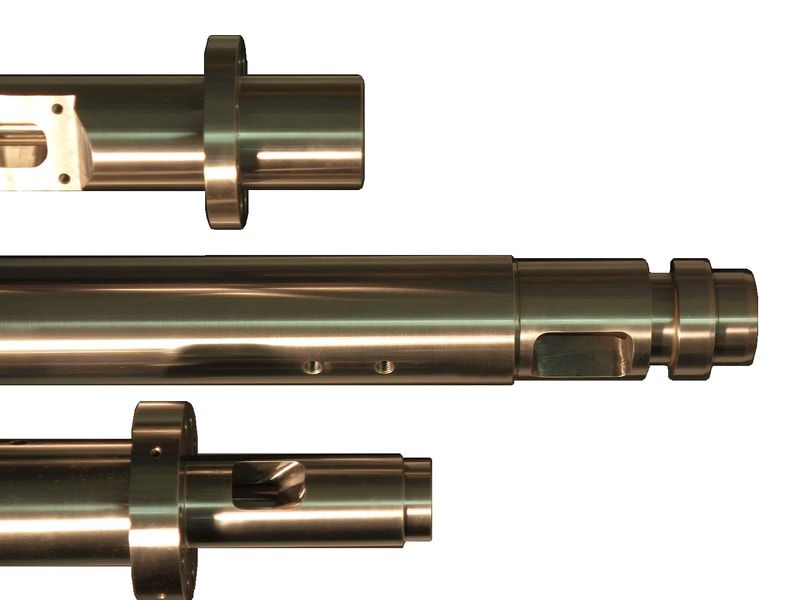

BARRELS FOR INJECTION MOLDING AND EXTRUSION

At Concor, all components that make up the injection unit command our careful attention. The barrel is the pressure carrying vessel with heat transfer demands for assisting in the plasticization of the material being processed. We specialize in bimetallic barrels and tool-steel-lined barrels. While more straight forward in design than complex screw and tip geometries the function is equally important. Concor's quality standards exceed those of the SPI.

DESIGN: Key characteristics we consider when designing, manufacturing, and selecting materials for barrels, include:

1. Dimensional stability of the lining alloy and backing steel:

a. Straightness is all-important to ensure that the screw and tip are centered over the entire length.

b. Materials are selected to withstand the cyclic pressures and change in temperature from shut down to processing, based on your application.

c. Concor assures the straightest barrels in the industry, exceeding SPI standards.

d. Feed thoat design, to promote free flow of feed material

2. Construction method and Alloy type:

a. Tool Steel lined and Bimatallic Barrels: Whether dedicated or custom molding, once we are aware of your process requirements, Concor will recommend either a tool-steel-lined barrel or bimetallic barrel and will apply the correct lining alloy to maximize the wear life of the barrel ID.

b. Please see below on this page, a reference chart on Barrel Material Characteristics of barrel materials used by Concor.

c. Concor stocks Reiloy bimetallic barrel blanks for fast delivery

1. Dimensional stability of the lining alloy and backing steel:

a. Straightness is all-important to ensure that the screw and tip are centered over the entire length.

b. Materials are selected to withstand the cyclic pressures and change in temperature from shut down to processing, based on your application.

c. Concor assures the straightest barrels in the industry, exceeding SPI standards.

d. Feed thoat design, to promote free flow of feed material

2. Construction method and Alloy type:

a. Tool Steel lined and Bimatallic Barrels: Whether dedicated or custom molding, once we are aware of your process requirements, Concor will recommend either a tool-steel-lined barrel or bimetallic barrel and will apply the correct lining alloy to maximize the wear life of the barrel ID.

b. Please see below on this page, a reference chart on Barrel Material Characteristics of barrel materials used by Concor.

c. Concor stocks Reiloy bimetallic barrel blanks for fast delivery

Concor supplies new, and rebuilds, complete barrels for Krauss Maffei machines, including the cast portions of the barrel assembly:

BARREL RELINING:

Barrels relining is a standard process in our manufacturing facility so we do not recommend that you throw out a worn barrel until you talk to us. Relined barrels perform equal to or better than the original barrel lining and are dimensionally straight and on size. Relined barrels often present an immediate cost saving over replacing with new.